Easy capsule ejection without interruption

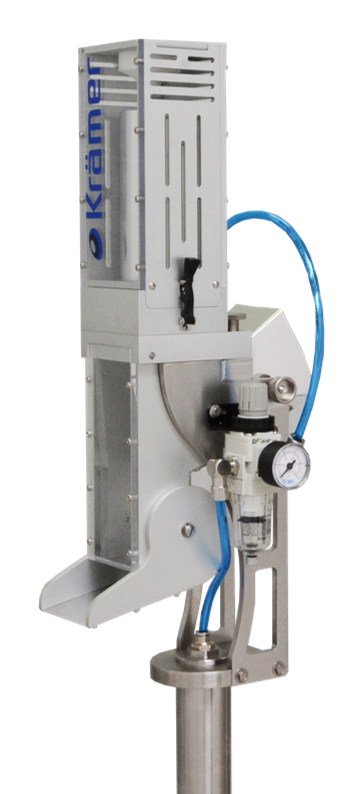

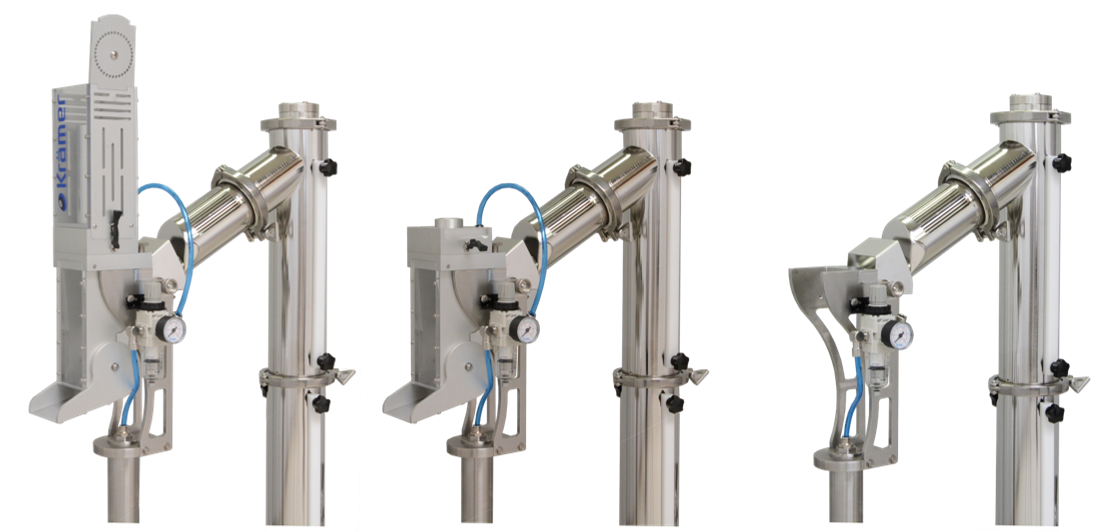

KCS10

With the empty capsule sorter the empty capsules are sorted out. Loose pieces of small remnants and capsules with low dosage are automatically sorted out. The machine can be connected to the main production line and other upstream and downstream devices.

- Ideal for all sizes and types of capsules filled with powder, granules or pellets

- Automatically rejects defective or underweight capsules and lose parts

- Operates with compressed air without any power supply

- Suitable to be used after a capsule polisher or metal detector

- Conveying speed: 300’000 capsules/hour

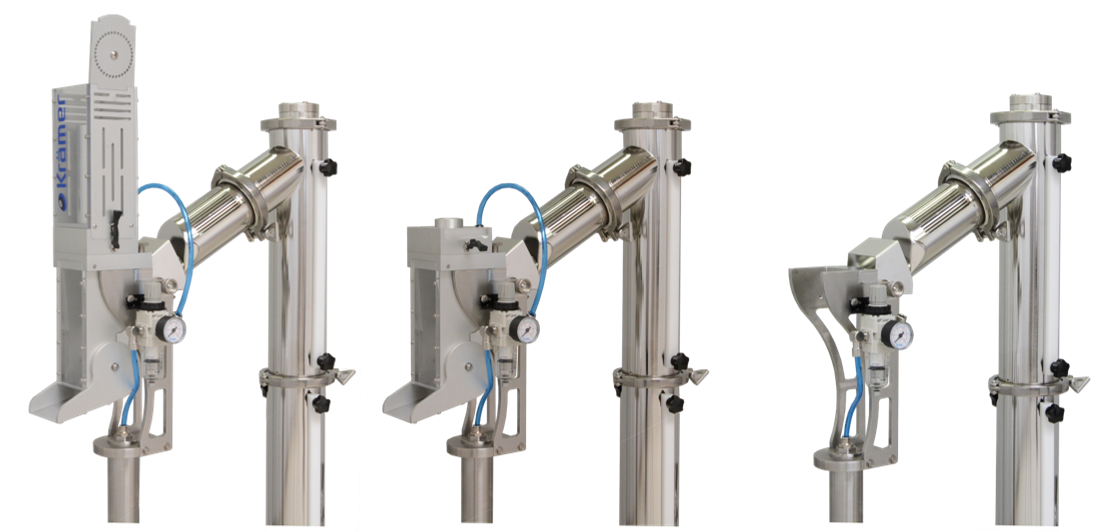

- Easy assembly and disassembly

Capsule sizes

00-4

Capacity

Up to 300'000 cph

EASE OF ASSEMBLY AND DISASSEMBLY

No tools are needed to assemble or disassemble the KCS10 for cleaning. All product contact surfaces are 316L stainless steel. All Krämer machines minimize the number of parts to be cleaned, and keep the weight of each part minimal for ease of handling.

Specifications

Product contacting parts

AISI 316L, anod. aluminium, PET-G

Weight

15 kg

Compressed air

Ø6/4mm, 0.25 l/min (p=3 bar)

Product inlet

68x38 mm

Product outlet

68x38 mm

Processing of tablets (var. forms ) Ø3-35 mm

Processing of mini/micro-tablets Ø1.5-3 mm

Processing of effervescent tablets Ø25-35 mm

Processing of capsules Nr. 4-00

Conveying speed capsule size Nr. 4

300'000 caps/h

Conveying speed capsule size Nr. 3

300'000 caps/h

Conveying speed capsule size Nr. 2

300'000 caps/h

Conveying speed capsule size Nr. 1

300'000 caps/h

Conveying speed capsule size Nr. 0

300'000 caps/h

Conveying speed capsule size Nr. 00

250'000 caps/h

Explosion protection ATEX 94/9/EG

N/A

OEL Level acc. SMEPAC

N/A

cGMP compliance

Option inlet adapter

Option outlet adapter

Option mini/micro-tablets

Option WIP manual/auto

Option validation documentation

Option material certificates